Standing Seam Clips: Types and When To Use

As you’re putting together the list of materials needed for a successful metal roof installation, you can’t overlook the small accessories as they are often the most important. Clips, for example, are critical to ensure standing seam metal roofs function as intended.

At Western States Metal Roofing, we manufacture concealed fastening systems that require clips for installation. Knowing which clip to use with your specific standing seam panel is vital to the performance of your roofing system.

In this article, we go over the types of standing seam roof clips and when you should you use each.

What Are The Different Types Of Standing Seam Clips?

- Floating clip

- Fixed clip

Standing Seam Panel Clips: What Is A Floating Clip?

A floating clip is a two-piece clip that is seamed/folded into the panel’s vertical leg. A floating clip is considered a type of sliding clip and is also known as an “expansion and contraction” clip. Unlike a one-piece clip that is commonly used with the snap lock standing seam system, the two-piece clips only allow for a small amount of movement with expansion and contraction because of the way it’s seamed into the panel leg.

The two-piece clip includes the body of the clip and the base. The base is secured to the substrate while the body is the part of the clip that is attached to the panel. Once that is complete, the female leg of the next panel is installed over the male leg and seamed into place. The clips are now locked in place, allowing the body and base of the clip to move independently of each other.

Floating clips are designed with a ½” stand-off, or space that elevates the roof panel above the substrate. This allows the standing seam panels the space it needs for thermal movement.

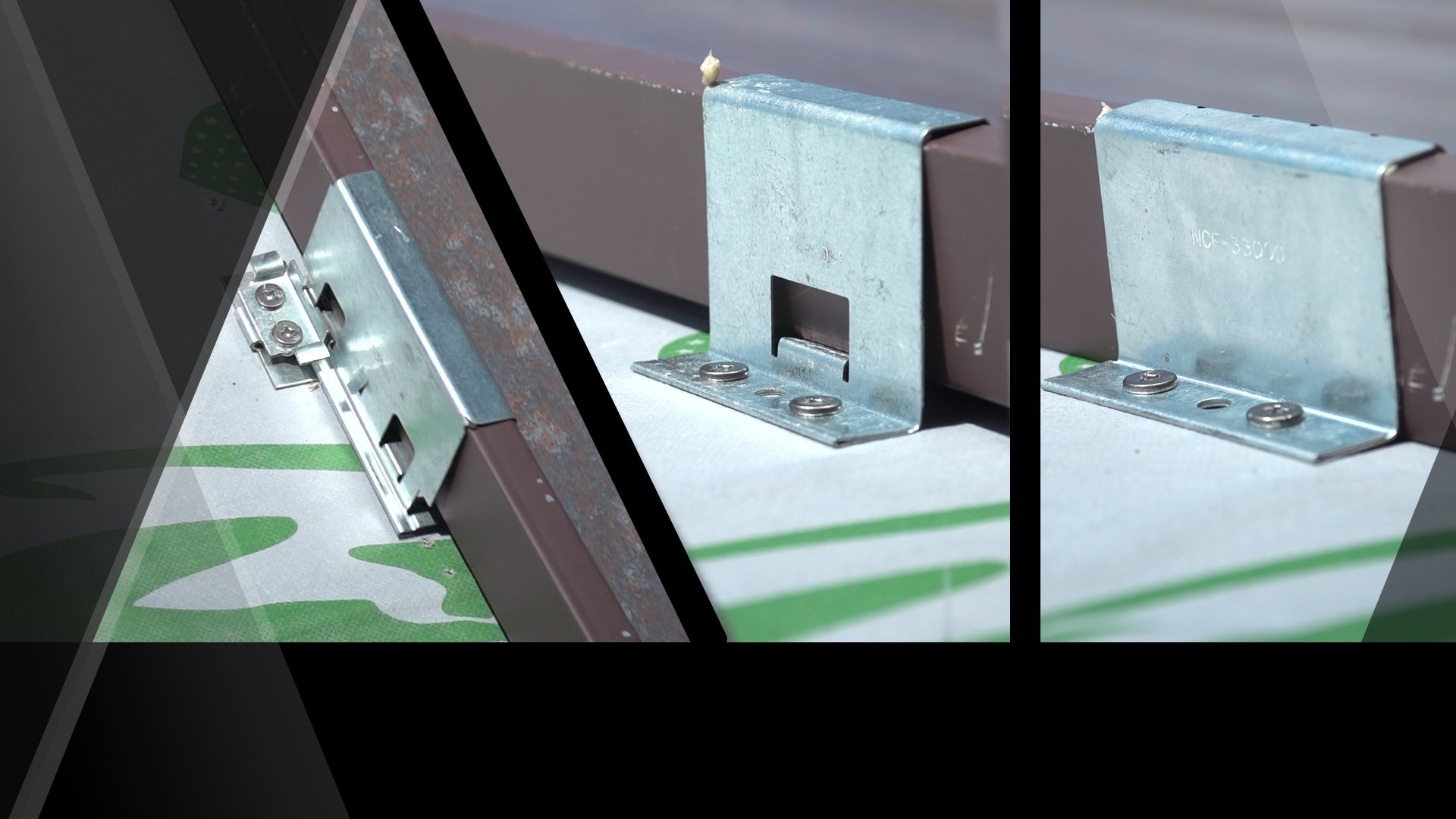

In This Photo: Standing Seam Floating Clip

When To Use Floating Clips On Standing Seam Roofs

Floating clips are recommended to be installed on mechanically seamed standing seam metal roofing panels only. They’re the best clip choice when the roofing panels are greater than 30 feet in length. Floating clips are also recommended in climates that experience extreme temperature changes as they allow for greater thermal movement than a fixed clip.

Standing Seam Panel Clips: What Is A Fixed Clip?

Fixed clips get their name from being “fixed” in place once they are installed. They are a one-piece clip that attaches to the leg of the panel and then fastened directly to the substrate. They do not allow movement for expansion and contraction. Fixed clips for mechanically seamed panels are available with or without a stand-off.

In This Photo: Standing Seam Fixed Clip

When To Use Fixed Clips On Standing Seam Roofs

Fixed clips are available for mechanically seamed and snap lock standing seam panels. The fixed clips are different depending on which type of standing seam panel that you choose. Snap lock standing seam will always use a fixed clip and mechanically seamed will use either a fixed, floating clip, or both.

Fixed clips for mechanically seamed panels are recommended to be installed when the panels are less than 30 feet. They are also the more economical choice and good to use when looking to have a more budget-friendly installation.

Fixed clips for mechanically seamed roofing do not allow for thermal movement, they are best suited for environments that do not experience extreme temperature changes to reduce stress on the clips and panels.

In addition, if you have a job that requires a floating clip then you will also use a fixed clips with a stand-off at the ridge or end wall. Additional fixed clips may be required depending upon the length of the panels.

Fixed clips for a snap lock metal roofing will allow for expansion and contraction.

Based On Your Clip Type, Clip Spacing Is Different

Every job is different and you should always consult an engineer to determine the correct clip spacing. Your load requirements and the climate will affect the type of clip and the clip spacing. Here are some general guidelines:

- For mechanically seamed panels over 30 feet - 1 floating clip should be placed every 2 Linear feet with 2 screws per clip and 2 fixed clips. The fixed clips with a stand-off will be placed at the ridge or end wall.

- For mechanically seamed panels that are under30 feet - Fixed clips, estimate using 1 clip and 2 screws every 2 Linear feet.

- For snap lock standing seam panels - Fixed clips, estimate using 1 clip and 2 screws every 2 to 3 Linear feet.

In This Photo: Standing Seam Fixed Clip & Floating Clip With Standoff

Choosing Your Standing Seam Clips

When choosing the right clip for your panel, take the following into consideration:

- Project budget

- Climate (thermal movement)

- Types of standing seam system

- Substrate type

Floating clips are recommended for:

- Mechanically seamed panels that are over 30 feet

- Climates that experience extreme temperature change

Fixed clips are recommended for:

- Snap lock standing seam

- Mechanically seamed panels that are under 30 feet

- Moderate climates

- Cost savings

Western States Metal Roofing has everything you need for a successful standing seam roof installation including clips, panels, underlayment, and more. If you have a materials list and know what your project requires, request a free quote today.