4 Common Problems With Rezibond Steel and How To Solve Them

Metal | Finishes | Education | rezibond steel

Rezibond steel is a popular choice, especially because the material is cost effective and it looks like an old galvanized panel that has started to turn dark gray.

Initially, this appears to be an excellent choice. However, if you have a metal roof or wall that requires Rezibond steel, there are several problems that can surface during and after the installation.

Here at Western State Metal Roofing, we have sold hundreds of Rezibond jobs, and there are problems that come up regularly.

Four Problems With Rezibond Steel

- White Rust

- No Warranty

- Scratches Easily

- Wet Stacking

Just in case you have a new roof installation or are looking at finishes for the next project, avoiding these four common Rezibond problems might help the designing process more efficiently down the line.

1. Rezibond May Develop White Rust

You can do everything perfectly on the job and there is still a likelihood that it will develop white rust after installation. It is not uncommon to have a job installed that looks gorgeous and gray after the contractor leaves, but then develops white rust streaks on the roofing or wall panels.

Nothing can be done to prevent the possibility of white rust. Furthermore, it is NOT a cause for rejection.

The only solution is warning the customer in advance. Let the owner know that there is no warranty and that white rust is a possibility in the future. Quite often the project owner wants something that looks old and has character.

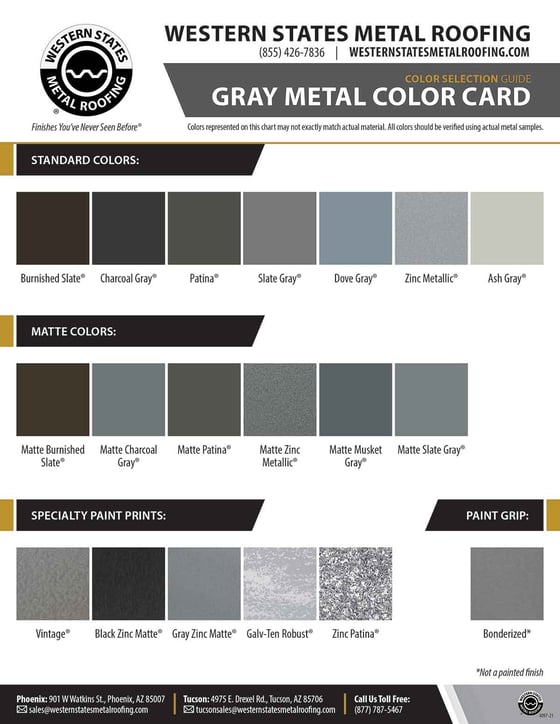

If this does not resolve the issue, then show them a specialty paint print that looks old, such as the color shown below.

2. No Warranty For Rezibond Steel

If you install Rezibond and do NOT paint the material, then it is not being used in the appropriate application. Rezibond steel is Galvanized G90 that has gone through a special process that makes it easier to paint.

The issue is not the longevity of the product — it has a galvanized G90 substrate so it is a suitable product in most environments. The main problem with Rezibond steel is it’s NON WARRANTABLE. In fact, we make our customers sign a Steelscape Rezibond Disclaimer.

Most people are under the impression there is a warranty with this product. The last thing that you want is a customer that thinks his roof will have a product warranty when none exist. There are two ways to solve the LACK OF NO WARRANTY issue.

- Offer the customer a different choice that will have a similar look, but has a standard paint warranty. One example is painted panels that are designed to look like a weathered gray finish. We are now able to recreate the look of an old panel with new steel.

- The project owner should be notified that Rezibond is intended to be painted. Using Rezibond steel without paint and in an exposed environment is NOT what the finish is designed for. Show the customer the Rezibond disclaimer.

3. Rezibond Scratches Easily

Rezibond steel scratches easily. These scratches are visible because the material has a dark finish with a galvanized coating underneath it. Typically, the scratches are tiny and plentiful. When you roll form the panel it will have hundreds of these scratches.

Use of strippable plastic film can prevent scratching. When we manufacture a Rezibond steel job, we apply the plastic during the roll forming of the panels. Then it’s peeled off prior bundling of the sheets.

When you buy Rezibond from our company you will get a product that has way less scratching than the competition.

4. Wet Stacking

Rezibond steel cannot get wet when it is stacked in a tight bundle. Whether that moisture is from rain and/or condensation from the weather it will turn into white rust.

Install Rezibond steel immediately and store the material in a dry place.

Avoid the Problems Before They Happen

If you have Rezibond on your job, it’s important to buy it from someone that understands this finish. You’ll want a company that protects their material from scratches. You will also want to educate the end user of the project prior to installation. This will eliminate any confusion about the expectations of the finished product.

If you enjoy this article then we recommend that you read these also: Bonderized Steel: A Comprehensive Guide

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.